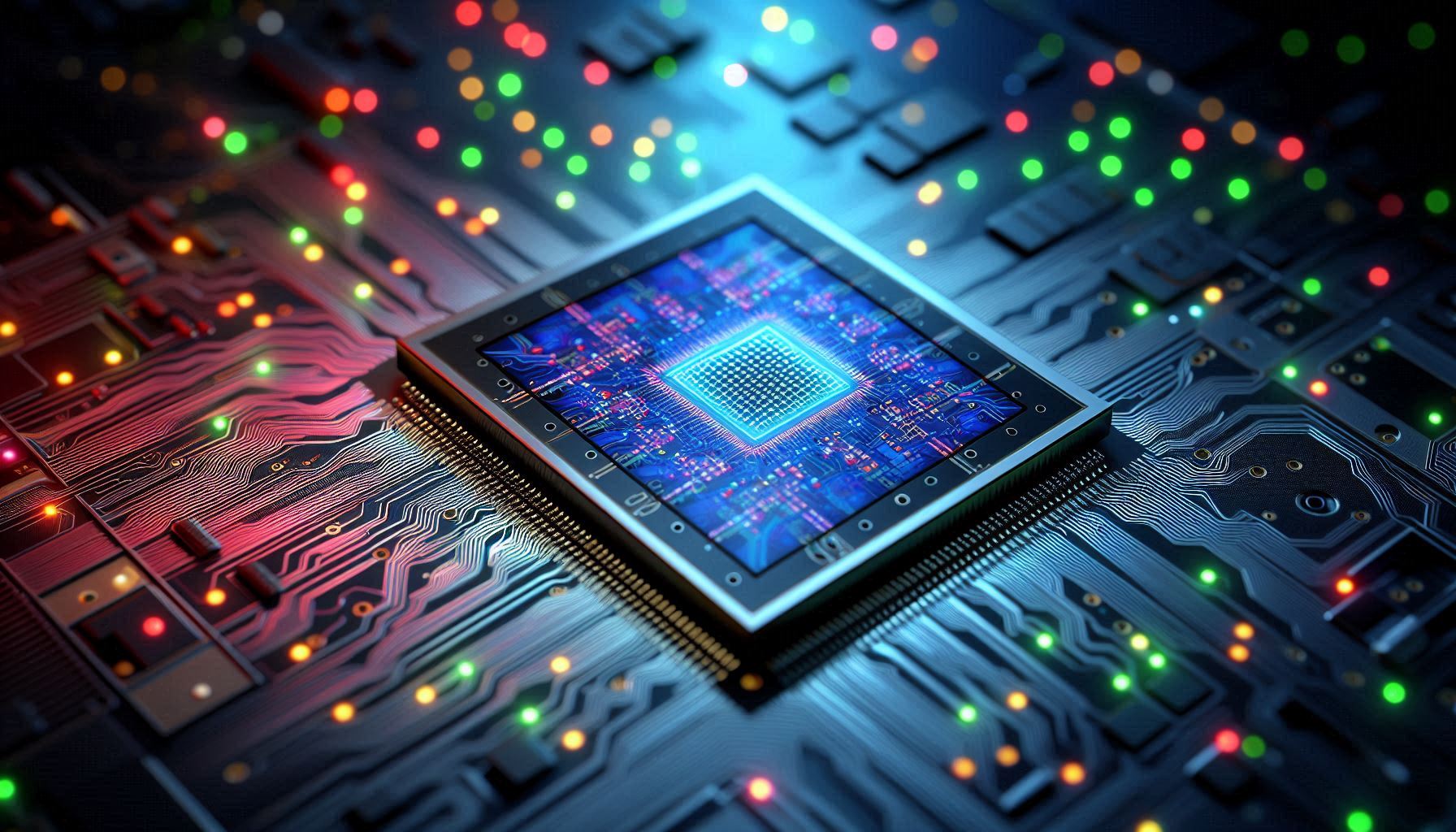

In the global race for technological sovereignty, semiconductors have become the new oil,an indispensable resource that underpins nearly every modern industry. They power the cars we drive, the phones we hold, the medical devices that sustain life, and the defense systems that protect nations. Yet Canada, a G7 country with a sophisticated research ecosystem and a reputation for stability, remains almost entirely dependent on foreign suppliers for the chips that keep its economy running.

This dependence is not merely inconvenient. It is dangerous. The chip shortages of 2020 and 2021 exposed how fragile global supply chains truly are. Automakers in Ontario were forced to idle production lines. Medical equipment manufacturers faced delays. Even defense procurement pipelines felt the strain. For a country that prides itself on resilience and innovation, the vulnerability was glaring.

Canada cannot afford to remain on the sidelines of the semiconductor era. The world is reorganizing its supply chains, and the countries that act decisively today will shape the next half-century of technological leadership. Those that hesitate will find themselves permanently dependent on others for the most critical input of the digital age.

This is why Canada must commit, in the short term, $10 to $15 billion to establish domestic chip-making capacity. It is not an extravagant ambition. It is a strategic necessity. And if federal and provincial governments are willing to offer 40 to 50 percent subsidies, Canada can build a viable semiconductor manufacturing base within a decade. Among all provinces, Ontario is uniquely positioned to lead this national effort.

A Strategic Imperative, Not a Luxury

The case for domestic chip manufacturing is not ideological. It is practical. Canada’s economy is deeply intertwined with industries that rely on a steady supply of semiconductors: automotive manufacturing, aerospace, telecommunications, clean energy, and advanced medical technology. As these sectors electrify and digitize, their dependence on chips will only intensify.

The geopolitical landscape adds another layer of urgency. Taiwan, which produces the majority of the world’s advanced chips, sits at the center of rising tensions. Any disruption, political, military, or environmental, would send shockwaves through global supply chains. Canada would be among the first to feel the impact.

For decades, Canada has relied on the assumption that global markets will always deliver. But the pandemic shattered that illusion. Nations are now competing fiercely to secure their own semiconductor futures. The United States, Europe, Japan, South Korea, and India are pouring tens of billions into domestic manufacturing. Canada, by contrast, has yet to articulate a national semiconductor strategy.

If Canada does not act now, it risks being left behind in a world where technological independence is increasingly synonymous with national strength.

The Price Tag, and Why It’s Worth It

A modern semiconductor fabrication plant is expensive. But it is also one of the most transformative investments a country can make. A facility capable of producing mature or mid-range chips, those used in cars, industrial equipment, medical devices, and defense systems, typically costs between $5 and $10 billion. Adding packaging, testing, and supply chain infrastructure brings the total to $10 to $15 billion.

This is well within Canada’s capacity. The federal government has funded projects of similar scale in energy, transportation, and aerospace. The difference is that a semiconductor fab does not merely create jobs; it creates an entire ecosystem. It attracts suppliers, engineers, technicians, and global partners. It anchors research and development. It strengthens national security. And it positions Canada as a serious player in the industries that will define the next century.

The return on investment is not measured in years, but in decades.

Why Subsidies Are Not Optional

No semiconductor company will build a fabrication plant in Canada without government support. This is not a Canadian problem; it is a global reality. The United States is offering generous incentives under the CHIPS Act. Europe is doing the same. India is offering subsidies as high as 70 percent. Japan and South Korea have long supported their semiconductor industries with public funding.

If Canada wants to compete, it must match these incentives. A subsidy in the range of 40 to 50 percent is not excessive. It is the price of admission. Without it, Canada will remain a spectator while other nations secure their technological futures.

Subsidies are not giveaways. They are catalysts. They reduce risk for private investors, accelerate construction timelines, and signal that Canada is serious about building a semiconductor industry that can stand on its own.

Why Ontario Should Lead

Among all provinces, Ontario stands out as the natural home for Canada’s semiconductor ambitions. It has the talent, the infrastructure, the industrial base, and the research institutions needed to support a fabrication ecosystem.

Ontario’s universities, Toronto, Waterloo, McMaster, Queen’s, Western produce some of the best engineers in the country. The province is home to Canada’s automotive heartland, a sector that increasingly depends on chips for electric vehicles, autonomous systems, and advanced safety technologies. It hosts major aerospace firms, telecommunications companies, and a thriving advanced manufacturing sector.

Ontario also has the infrastructure that fabs require: reliable power, abundant water, transportation networks, and proximity to the U.S. market. And it has experience supporting large-scale industrial projects, from automotive plants to battery factories.

If Canada is serious about building a semiconductor industry, Ontario is the province best positioned to lead the charge.

A National Strategy for a New Era

To succeed, Canada needs more than funding. It needs a coordinated national strategy that brings together federal leadership, provincial commitment, industry partnerships, and workforce development.

The federal government must take the lead by establishing a Canada Semiconductor Mission, allocating the necessary funding, and negotiating partnerships with global foundries. Provinces must complement this effort with land, infrastructure, and additional subsidies. Universities and colleges must develop programs to train the technicians and engineers that fabs require. And Canada must work with international partners, especially in the United States, Europe, Japan, and South Korea, to build supply chain resilience.

This is not a five-year project. It is a generational one. But the first step must be taken now.

The Cost of Doing Nothing

The alternative to action is not stability. It is decline. Without domestic chip-making capacity, Canada will remain vulnerable to global disruptions. It will struggle to compete in industries that depend on secure access to semiconductors. It will fall behind in the technologies that will shape the future: artificial intelligence, quantum computing, robotics, clean energy, and advanced manufacturing.

Canada has the talent. It has the resources. It has the stability and the credibility that global partners value. What it lacks is urgency.

A Decisive Moment

The world is entering a new technological era, one defined not by abundance but by strategic competition. Nations are no longer content to rely on global markets for critical technologies. They are building their own capabilities, securing their own supply chains, and investing in their own futures.

Canada must do the same.

A commitment of $10 to $15 billion, backed by 40 to 50 percent subsidies, is not merely an economic decision. It is a declaration that Canada intends to shape its own destiny in the digital age. It is a recognition that technological independence is essential to national resilience. And it is an opportunity for Ontario to position itself as the front-runner in a sector that will define the next century.

The question is not whether Canada can afford to invest in semiconductor manufacturing.

The question is whether it can afford not to.